Beyond Durability: Why Ultra 800X is the Ultimate Fabric for Wet and Wild Adventures

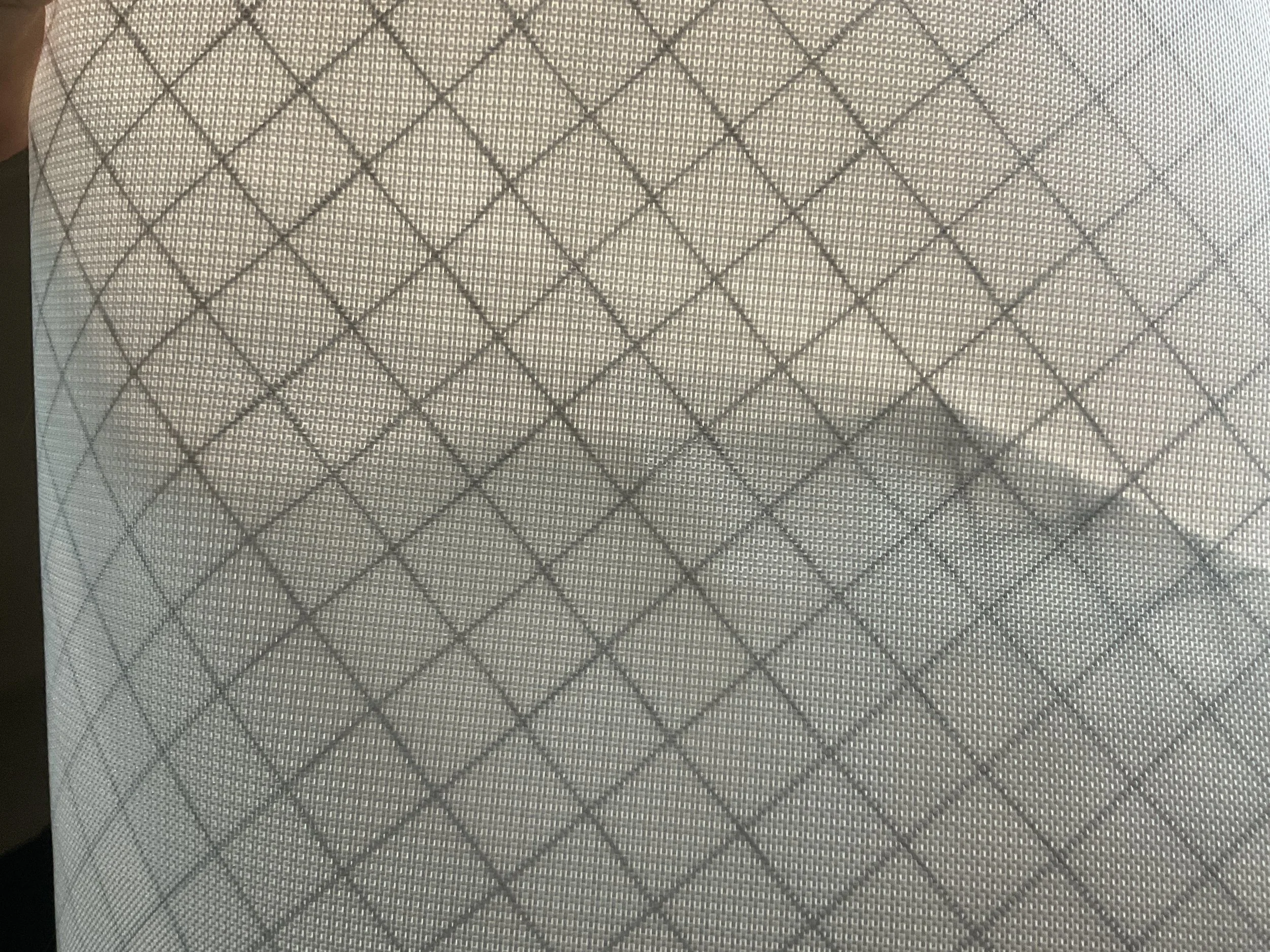

The patented rip stop woven from UHWMPE fibers. Challenge Ultra 800x

Is your gear's durability just about longevity? Discover how Ultra 800X's UHMWPE fibers offer unmatched strength, zero water absorption, and a lighter environmental footprint—making it the only choice for serious climbers, cavers, and canyoneers.

Packs made from UHWMPE dry faster and stay lighter.

We’ve all seen the ghost packs. The faded shred of nylon snagged on a limestone lip. Silently sitting in a cave for eons. The busted zipper abandoned at the base of a wall. This isn’t just gear failure; it’s an environmental stain on the places we love most. For those of us who venture into the vertical and watery world, “durability” can’t just be about surviving the climb—it must be about performing when soaked and protecting the rock, the water, and the scenery for perpetuity.

At Ether Forged, we asked a different question: What if the toughest fabric was also the smartest in water and the most responsible? The answer is the heart of every pack we build: Challenge Ultra 800X, woven from UHMWPE fibers.

What Is Ultra 800X? The Technical Forge

Let’s get granular. This isn’t marketing fluff; it’s materials science.

Abrasion Resistance: Withstands over 16,00 rubs on the ASTM test—over 500% more than standard 1000D Mil spec legacy nylon cordura. It doesn’t just resist sandstone; it scoffs at it.

Tear Strength (ATSM D2261): Warp: 250+ lb. | Fill: 250+ lb.

Tensile Strength: The high-tenacity UHMWPE yarns offer an unparalleled strength-to-weight ratio. This means we use less material to achieve greater protection, shaving critical grams off your back on every rappel.

The Wet Strength Advantage: Why Nylon Fails.

For decades, nylon has been the default. But it has a hidden, critical flaw: it absorbs water. This is why they apply a nasty DWR waterproof coating that will fail. A submerged nylon pack can absorb up to 8% of its weight in water, becoming heavier and weaker due to a process called hydrolysis, which breaks down its fibers.

Ultra 800X, built on UHMWPE, is fundamentally different:

· Zero Water Absorption: UHMWPE fibers are hydrophobic. They do not absorb a single drop of water. Your pack’s fibers strength and weight remain absolutely unchanged, whether it’s bone-dry or fully submerged.

100% Strength Retention: A wet nylon pack can lose over 15% of its tensile strength. A wet Ultra 800X pack retains 100% of its strength. The integrity of every stitch remains intact when you need it most.

Rapid Drainage & Dry Time: We design our packs with rapid drainage in mind. Since the fabric itself won’t hold water, it sheds weight the moment it leaves the pool and is dry to the touch in minutes. The fabric will be almost translucent in the a wet environment.

The Recycled Core: Where Performance Meets Principle.

Recylcle

But raw performance is only half the story. The soul of Ultra 800X is what it’s made from. This fabric is woven using high-performance yarns made from 100% post-consumer recycled (PCR) materials.

What does that mean for you?

1. You Directly Reduce Waste: Choosing an Ether Forged pack diverts plastic waste from oceans and landfills, giving it a second life as elite adventure equipment.

2. You Drastically Lower Carbon Footprint: Manufacturing with PCR content consumes significantly less energy and water than producing virgin nylon.

3. You Become a Steward: For a caver, this means a pack that won’t degrade and shed microplastics into pristine underground waterways. Your choice protects the very ecosystems you’re exploring.

The Ether Forged Guarantee.

We don’t use Ultra 800X because it’s easy or cheap. We use it because it’s the only material that meets our non-negotiable standards for performance and planetary responsibility. It is the physical manifestation of our promise to you and to the wild places we cherish. If you return your fully used pack to us we will recycle the materials to close the sustainable lifecycle.

Your climb deserves the best protection. Your planet does, too.

Experience the unmatched blend of ultralight performance, total wet strength, and undeniable ethics.